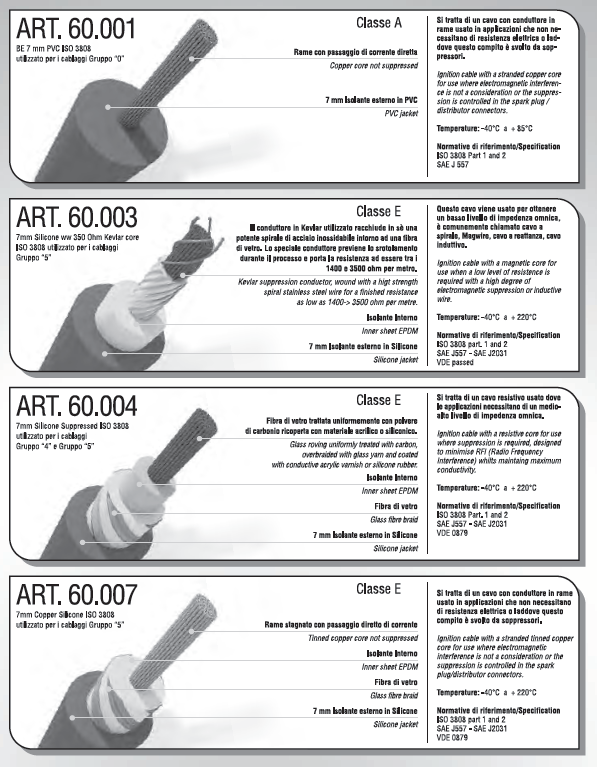

The ignition wire is made up of a core called conductor, a first level sheath generally in EPDM or silicone, and an outer sheath in silicone or other material.

The certification to define an ignition wire is ISO 3808 part I and II, to which other international standards such as SAE and VDE refer.

The internal combustion engine or also called internal combustion engine is used to convert the thermal energy created by the combination of air, fuel and spark to give life to the movement of the vehicle.

Vital importance is the “carrier” of the spark, which can be the spark plug wire and/or an ignition coil.

The system then performs the function of vital to the operation of the vehicle because the synchronization of the correct amount in the mixture of fuel and air the spark creates the primary source of movement.

So getting the spark to arrive at the right time, with the correct amount and power are the essential element of the engine’s torque propulsion.

Therefore, the ignition cable and/or the pencil coil become a fundamental element to get the electricity to the spark plug, asserts Paolo Braia, Production and Logistics Manager Brecav Srl, a spark plug cable and/or a pencil coil not in perfect condition causes a delay in the arrival of the spark and consequently the combustion chamber fills up with the mixture of fuel and air and causes greater discharges of CO into the environment, deteriorating the downstream parts of the system and polluting the environment more.

The ignition cable and/or the ignition coil ensure that the high voltage current is properly distributed to the spark plugs. In essence, they transmit energy to the system, they protect from radiated interference, the shielding is through the conductor, which in turn is protected by at least two layers of silicone sheaths (or other material) or through resistive caps.